unconventional raw

enhanced versatility across different applications.

what is

timeplast-raw

made from?

A revolutionary thermoplastic material crafted from a proprietary blend of alcohol, cellulose, and vinegar. Known as Timeplast resin, this substance transforms under heat and pressure during molding, increasing its molecular weight significantly to create a durable, yet fully dissolvable polymer.

Key Features and Advantages of Timeplast

-

Programmable Lifespan:

Timeplast can be engineered to last from just 60 seconds up to 60 years in water. The duration before dissolution is precisely controlled by adjusting the Molecular Weight and part thickness to suit specific needs.

-

Leaving No Trace:

Once dissolved in sufficient water, Timeplast leaves behind no plastic footprint or toxic byproducts, ensuring an environmentally friendly lifecycle from production to dissolution.

-

Enhanced Sustainability:

By eliminating the need for in-house polymerization, Timeplast conserves energy compared to traditional plastic production, enhancing its sustainability credentials.

-

Versatile Manufacturing:

Compatible with conventional plastic manufacturing processes such as injection molding, extruding, blown film, and thermoforming, Timeplast seamlessly integrates into existing production lines.

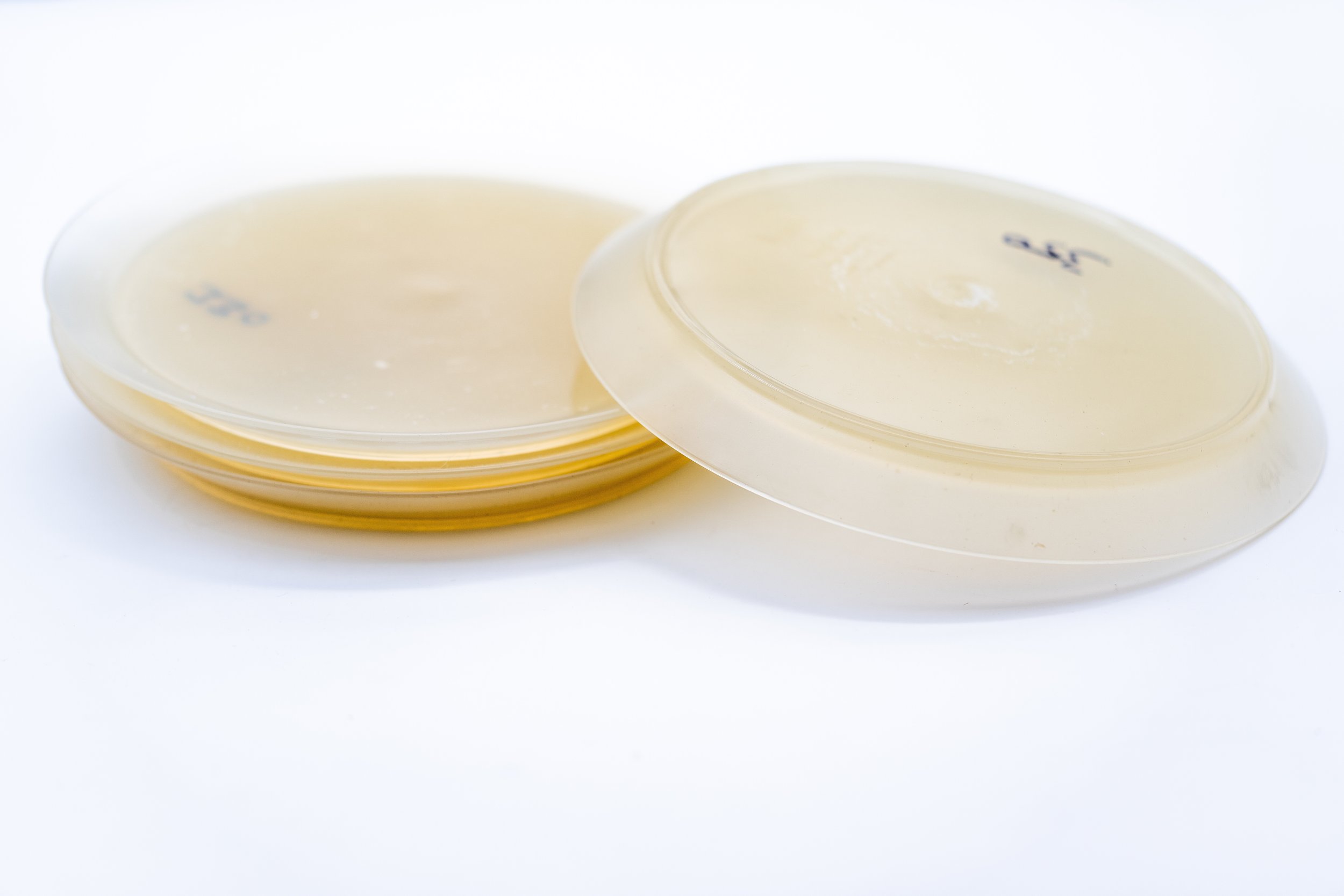

THERMOFORMED

TIME-PLATE

INJECTED

TIME-PLATE

3D-PRINTING

time-mass

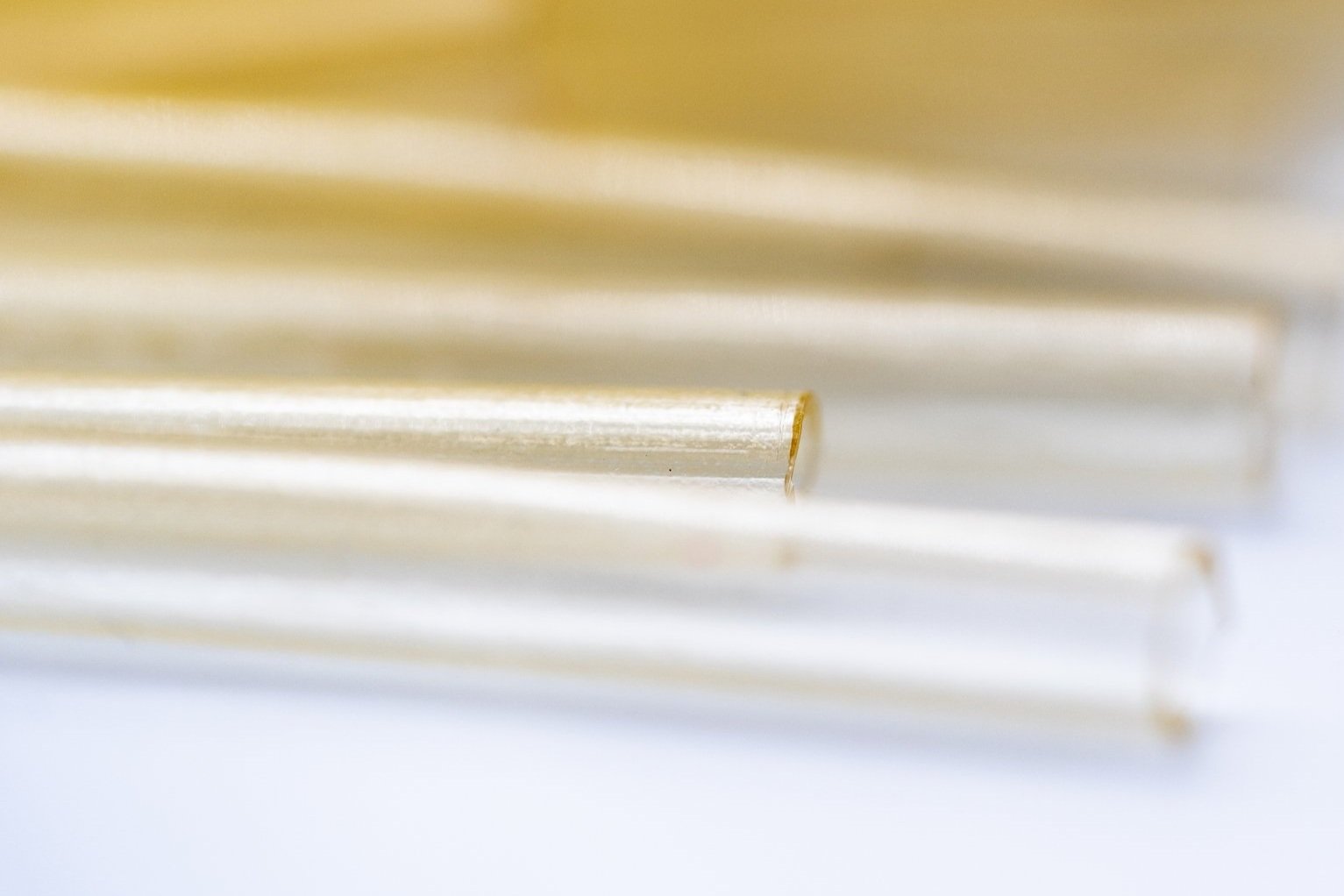

EXTRUDED

TIME-STRAW

TIME-MADE

BLOW-MOLDED

THERMOFORMED

TIME-tray

CLOTHING AND MORE

time-THREAD

Unlock

the unconventional.

The publication contains over 60 pages of in-depth content, offering a comprehensive exploration of Timeplast's raw materials and processes.